Fully automatic tapping machine, adopts PLC control and gear

transmission. It is synthesized from feeding,

clamping, tapping, and unloading, and can process

internal threads with different pitches. One person

can operate multiple machines. It greatly saves labor

costs, reduces labor intensity, and improves

production safety. It is an ideal special equipment for

machining internal threaded workpiece at present.

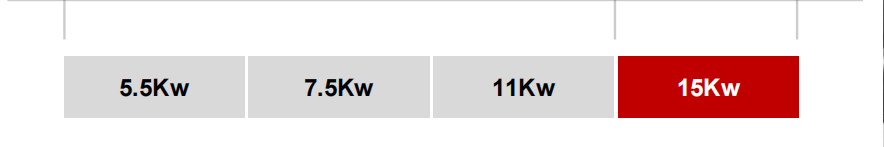

Motors with different powers are equipped with high-quality speed reducers with different speed ratios, which perfectly adapts to the torque required for machining large threads and pitches of different materials.

Standard Customize

The main shaft stroke of 20~120mm can meet the requirements of blind holes, through holes, and different thread processing lengths. Adjusting the stroke distance can effectively improve production efficiency.

When machining different specifications of threads, the matching rotational speed varies depending on the amount of cutting and the required tapping torque. Adjusting the speed according to different specifications of thread processing can effectively ensure production efficiency.

Dual stations operate synchronously from feeding, clamping, tapping and unloading, resulting in a seamless operation and higher efficiency.

Choose different human-computer interactive operation panel modes for different operating groups, and button operation is more suitable for ordinary workers.

According to the overall dimensions of the workpiece you need to process, customize the feeding and clamping system structure to make it more suitable for your workpiece processing need.

Suitable for workpiece material

Suitable for workpiece material

thread

thread

thread

thread

thread

thread

Double thread

Double thread

Customer artifact case

Available in styles

Type E(Economic)

Type F(Functional)

Available in different specifications

| Main motor Power | 5.5Kw | 7.5Kw | 11Kw |

|---|---|---|---|

| Workpiece ID range | M16~M32(≤3.0P) | M16~M40(≤3.5P) | M16~M45(≤4.0P) |

| Workpiece Length range | 20~100mm | 20~110mm | 20~110mm |

| Accuracy | 6H | 6H | 6H |

| Controlling type | PLC | PLC | PLC |

| Dynamic | Pneumatic, Hydraulic and Electric | Pneumatic, Hydraulic and Electric | Pneumatic, Hydraulic and Electric |

| Frequency converter | Yes | Yes | Yes |

| Alarm light | Yes | Yes | Yes |

Creat quality with craftmanship, focus on achieving professionalism.