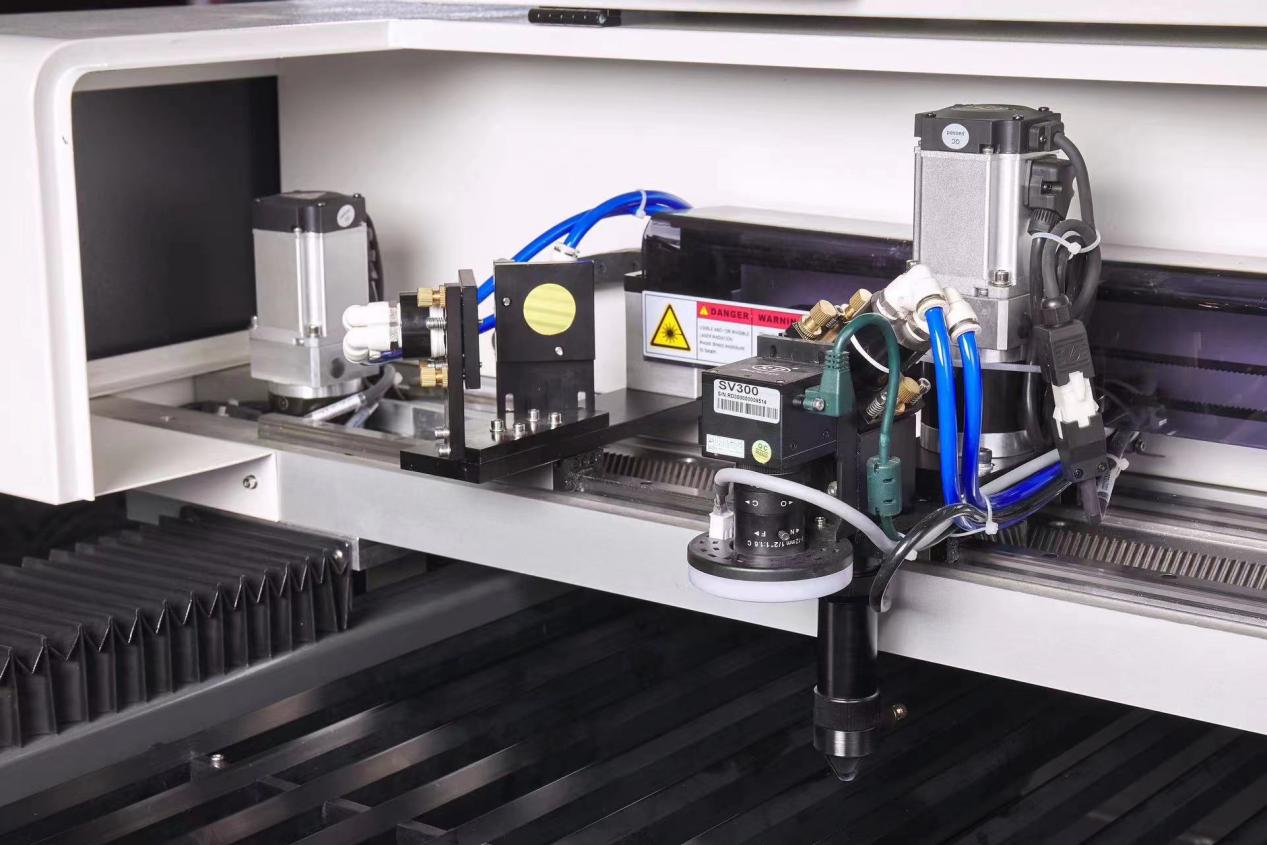

Fully automatic tapping machine, adopts PLC control and gear

transmission. It is synthesized from feeding,

clamping, tapping, and unloading, and can process

internal threads with different pitches. One person

can operate multiple machines. It greatly saves labor

costs, reduces labor intensity, and improves

production safety. It is an ideal special equipment for

machining internal threaded workpiece at present.

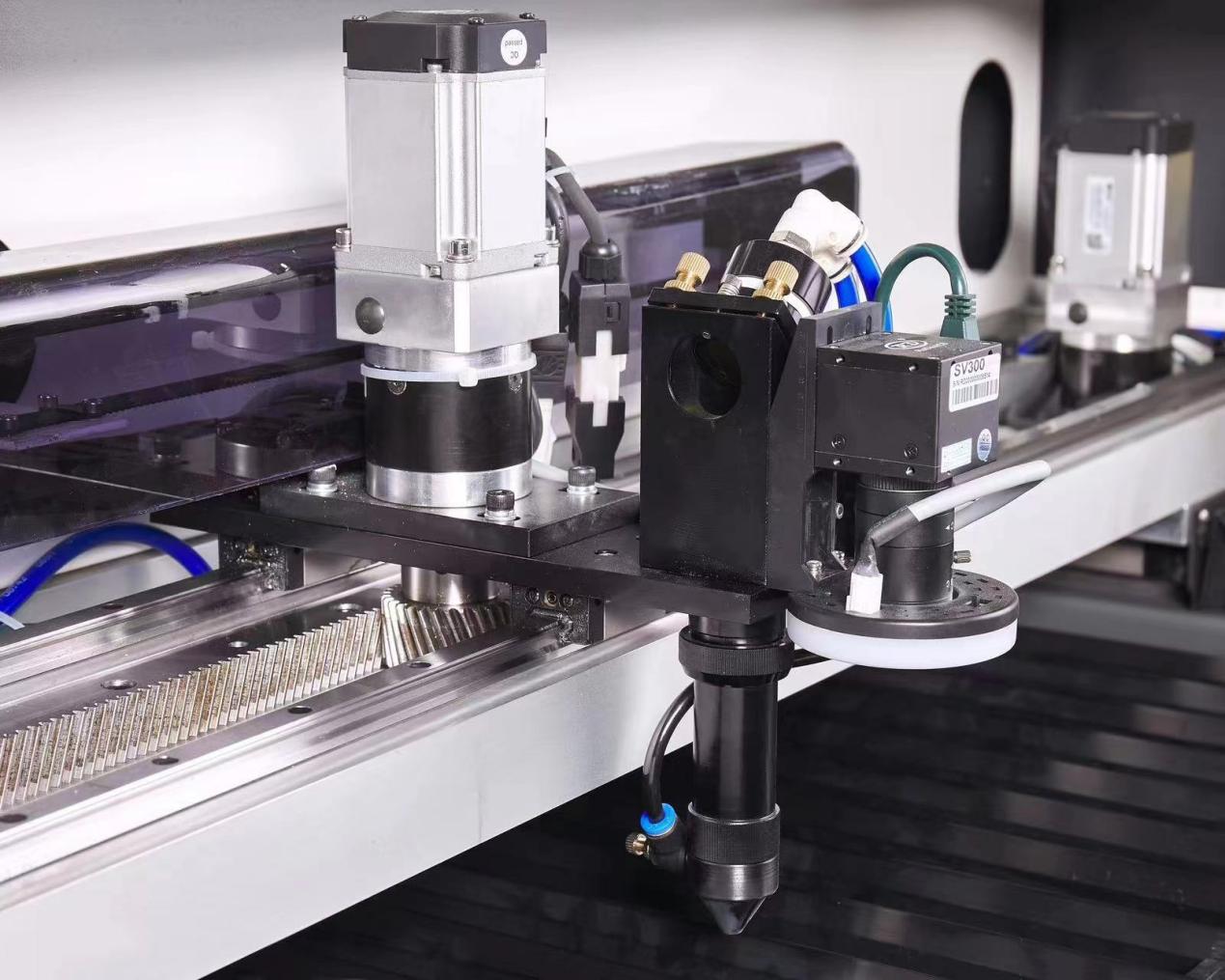

Motors with different powers are equipped with high-quality speed reducers with different speed ratios, which perfectly adapts to the torque required for machining large threads and pitches of different materials.

Standard Customize